|

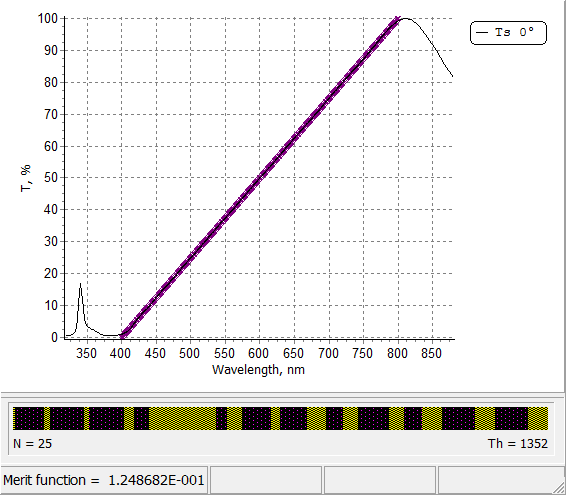

Designing of RAMP coating using Needle Optimization AUTO (in order to observe design process put mouse over the picture) |

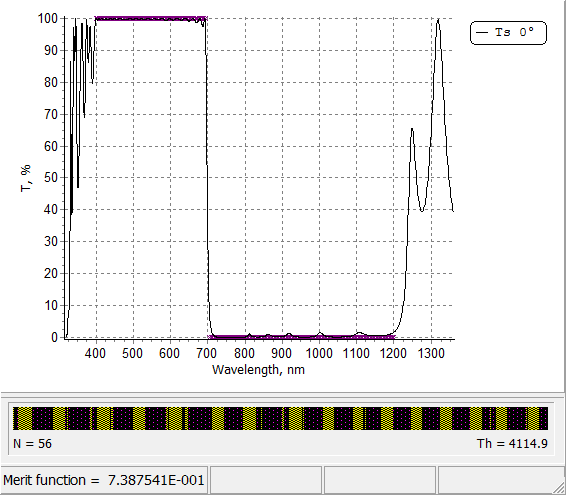

Designing of Hot Mirror using Gradual Evolution (in order to observe design process put mouse over the picture) |

See the details in our publications. |

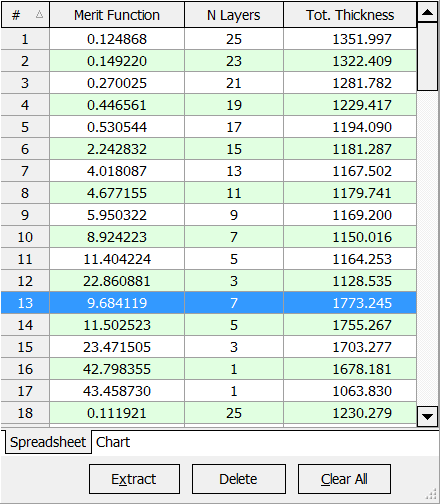

| All designs are stored in the corresponding database which is called the History database. This feature adds flexibility to the design procedure because you can easily return to the previous steps of the design procedure and try to apply other design approaches. |  |

Look our video examples at YouTube

OptiLayer videos are available here:

Overview of Design/Analysis options of OptiLayer and overview of Characterization/Reverse Engineering options.

The videos were presented at the joint Agilent/OptiLayer webinar.