| Random Optimization is useful in two cases:

1. It is difficult to find a suitable starting design for the refinement procedure. In such cases it may be useful to carry out a sequence of optimization procedures with random starting designs. Because of highly efficient optimization algorithms used in OptiLayer, this design approach often provides good results. This procedure is typically used for solving complicated design problems when good starting designs are unknown. 2. It is required to generate a set of different designs for finding a design with better manufacturability. |

|

|

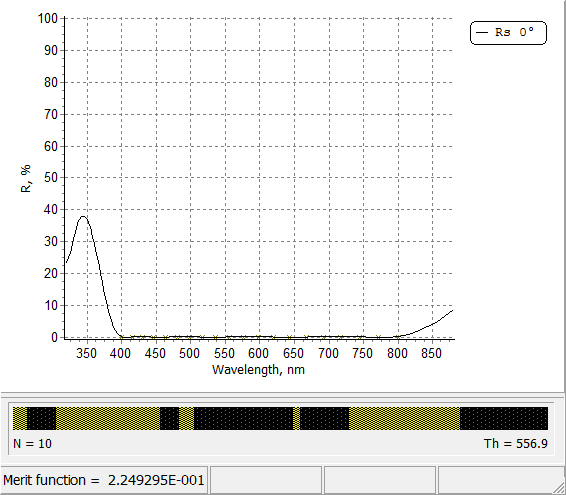

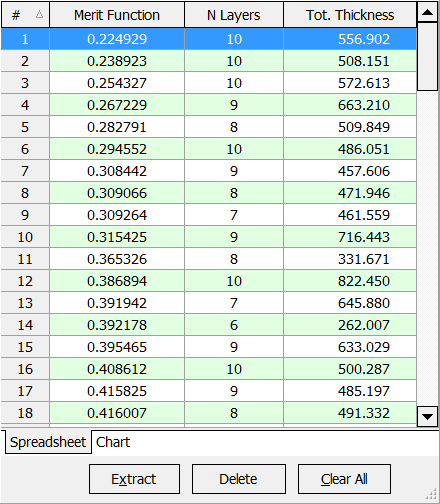

OptiLayer generates a sequence of starting designs with the indicated number of layers and average layer thickness. Each design is optimized by one of the chosen numerical methods. The process continues until you interrupt it. The best results are being stored in the Collection storage (see left panel). These results can be used later as starting designs for the needle optimization procedure or for the gradual evolution. They can be easily extracted from the Collection storage and loaded into memory.

It is also possible to use Design mode where the search area of the Random Optimization is specified as some vicinity of the loaded design. It is possible to set constraints for each layer thickness, usually it significantly improves computational performance and quality of obtained solutions. Specified layer thickness limits are taken into account both when starting designs are specified and when local optimization procedures are performed. |

OptiLayer provides user-friendly interface and a variety of examples allowing even a beginner to effectively start to design and characterize optical coatings. Read more…

Comprehensive manual in PDF format and e-mail support help you at each step of your work with OptiLayer.

If you are already an experienced user, OptiLayer gives your almost unlimited opportunities in solving all problems arising in design-production chain. Visit our publications page.

Look our video examples at YouTube

OptiLayer videos are available here:

Overview of Design/Analysis options of OptiLayer and overview of Characterization/Reverse Engineering options.

The videos were presented at the joint Agilent/OptiLayer webinar.