| Inhomogeneous Refinement procedure starts with a single layer of a specified thickness and with some refractive index and extinction coefficient. A number of subdivisions (steps) of the initial single layer into thin layers of equal initial thickness is also specified.

At the first stage of the Inhomogeneous Refinement refractive indices and thicknesses of thin layers are varying in order to optimize the merit function. At the second stage, the obtained inhomogeneous design is converted to a multilayer stack consisting of materials, loaded to memory. The converted design is re-optimized at this stage if necessary. The final design is automatically exported to OptiLayer and can be used for further processing, for example, with the help of the Needle Optimization procedure. |

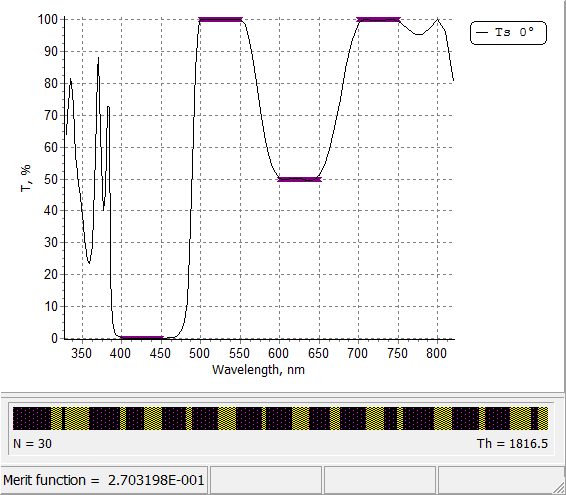

A filter designed with the help of Inhomogeneous Refinement (in order to see the design process, put the mouse on the picture) |

See the details in our publications:

|

|

OptiLayer provides user-friendly interface and a variety of examples allowing even a beginner to effectively start to design and characterize optical coatings. Read more…

Comprehensive manual in PDF format and e-mail support help you at each step of your work with OptiLayer.

If you are already an experienced user, OptiLayer gives your almost unlimited opportunities in solving all problems arising in design-production chain. Visit our publications page.

Look our video examples at YouTube

OptiLayer videos are available here:

Overview of Design/Analysis options of OptiLayer and overview of Characterization/Reverse Engineering options.

The videos were presented at the joint Agilent/OptiLayer webinar.