| With the current state-of-the-art in designing optical coatings, a reliable monitoring of their production becomes a key to success in many application areas. There exists a great variety of different monitoring approaches.

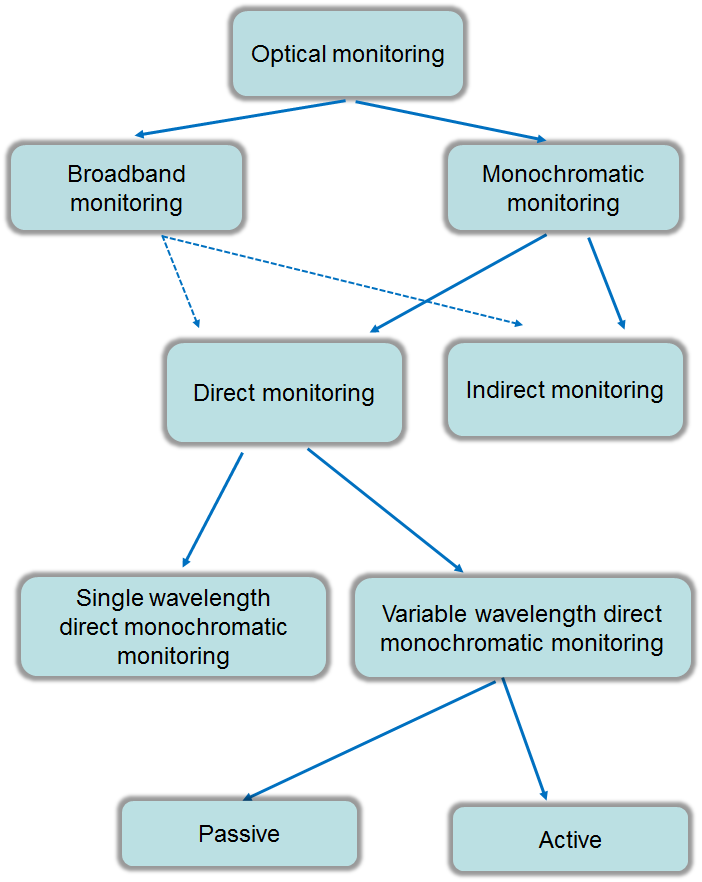

A primary subdivision of monitoring techniques is their subdivision into non-optical techniques (quartz crystal and time monitoring) and optical monitoring techniques. Optical monitoring techniques can be then subdivided into monochromatic monitoring (on-line measurements are performed at a single or several subsequent wavelengths) and broadband monitoring (on-line measurements are performed in a spectral range) techniques.

Monitoring techniques can be divided into direct and indirect ones. In the case of direct monitoring, transmittance or reflectance measurements are performed on at least one of the coatings to be manufactured while in the case of indirect monitoring layer thicknesses are monitored on separate witness substrates.

|

Classification of optical monitoring strategies. |

|

OptiLayer Monitoring options include:

OptiLayer Automation options and OptiReOpt library propose tools for on-line characterization and re-optimization of optical coatings. |

See details in our publications:

|

Look our video examples at YouTube

OptiLayer videos are available here:

Overview of Design/Analysis options of OptiLayer and overview of Characterization/Reverse Engineering options.

The videos were presented at the joint Agilent/OptiLayer webinar.