| Monochromatic Monitoring Simulation is OptiLayer tool that is aimed for performing experiments on computational manufacturing of optical coatings.

Monochromatic Monitoring Simulation option allows you to perform computational experiments simulating deposition processes in vacuum chambers equipped with monochromatic monitoring devices. You can specify all major factors causing errors in layer thicknesses:

|

Monitoring wavelengths are taken from the Monitoring spreadsheet. These wavelengths can be specified by an optical coating engineer or chosen automatically with the help of the advanced monitoring strategies.

|

| Example illustrating advanced monitoring strategies.

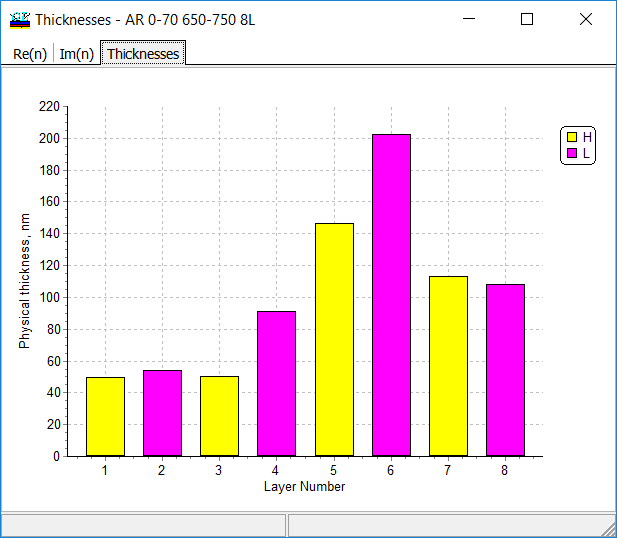

8-layer AR coating working in the spectral range from 650 nm to 750 nm, and in angular range from 0 to 70 degrees. Light is non-polarized. Substrate is Suprasil, layer materials are Nb2O5 and SiO2.

Simulation parameters:

|

Monitoring wavelength is 700 nm – middle of the antireflection spectral range Monitoring wavelength of 621 nm is obtained with the help of the advanced monochromatic monitoring strategy of OptiLayer. Monochromatic monitoring simulations help to production yields in the case of these two monitoring wavelengths. Estimation of the production yield \(Y\) is the ratio of successful and total simulated runs. To distinguish between successful and unsuccessful deposition runs, the range targets are to be introduced. In this problem, the range target is defined as \(R\le 9.5\%\) in the spectral range from 650 nm to 750 nm. |

| With monitoring wavelength of 700 nm production yield is 0%:

All simulated coatings are outside of the allowed corridor \(R\le 9.5\%\).

|

With monitoring wavelength of 621 nm production yield is 0%:

All simulated coatings are inside of the allowed corridor \(R\le 9.5\%\).

|

Look our video examples at YouTube

OptiLayer videos are available here:

Overview of Design/Analysis options of OptiLayer and overview of Characterization/Reverse Engineering options.

The videos were presented at the joint Agilent/OptiLayer webinar.