|

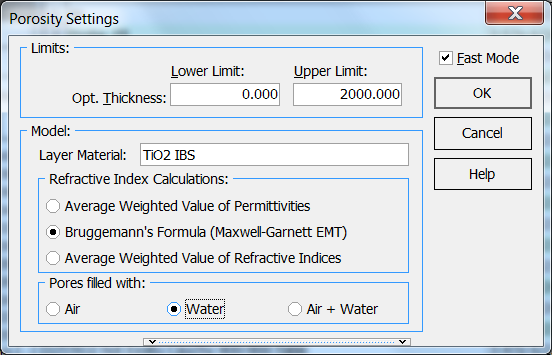

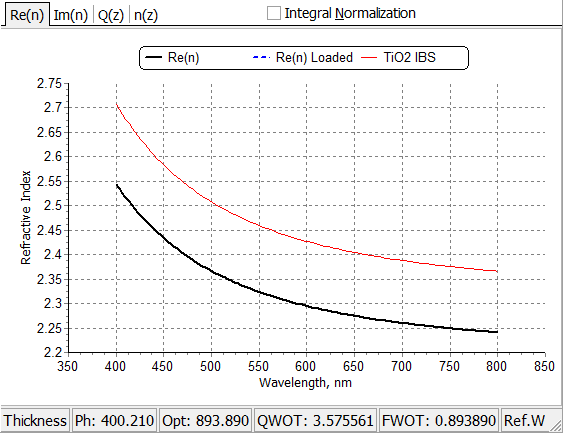

In porosity characterization option refractive index of the layer is determined as a mixture of a material selected from Layer Material database and Air, Water or Air+Water. You can select how the refractive index of the porous material is calculated: average weighted of permittivity, Bruggemann formula or average weighted of refractive indices. This option is typically used for verification of characterization results. For example, refractive index of very dense IBS TiO2 film can be considered as the refractive index of the bulk material (see picture on the right). If it is assumed that the pores in e-beam evaporated film are filled with water, then the calculated packing of evaporated TiO2 is equal about 85%. Find the details in our publications:

|

|

|

|

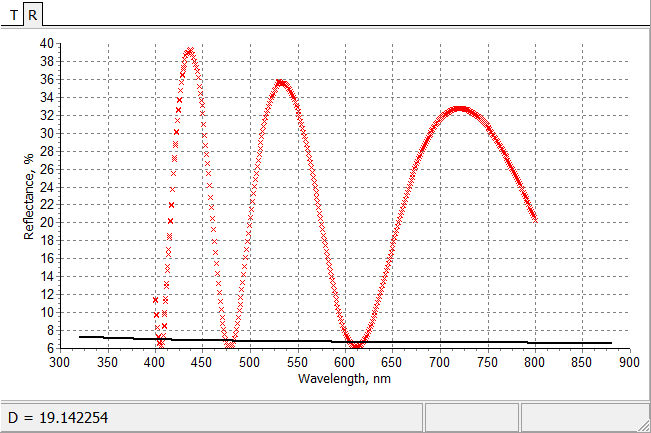

Initial and final fittings of experimental reflectance data related to e-beam evaporated TiO2 film (put the mouse on and out of picture) |

OptiLayer provides user-friendly interface and a variety of examples allowing even a beginner to effectively start to design and characterize optical coatings. Read more…

Comprehensive manual in PDF format and e-mail support help you at each step of your work with OptiLayer.

If you are already an experienced user, OptiLayer gives your almost unlimited opportunities in solving all problems arising in design-production chain. Visit our publications page.

Look our video examples at YouTube

OptiLayer videos are available here:

Overview of Design/Analysis options of OptiLayer and overview of Characterization/Reverse Engineering options.

The videos were presented at the joint Agilent/OptiLayer webinar.

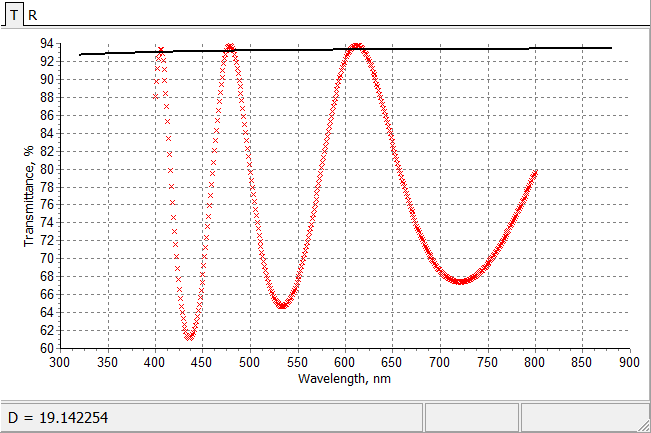

Initial and final fittings of experimental transmittance data related to e-beam evaporated TiO2 film (put the mouse on and out of picture)

Initial and final fittings of experimental transmittance data related to e-beam evaporated TiO2 film (put the mouse on and out of picture)