|

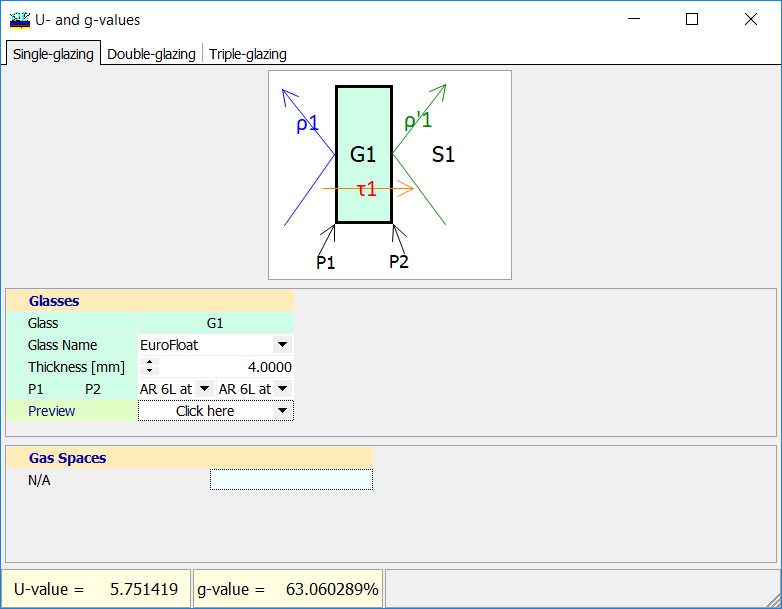

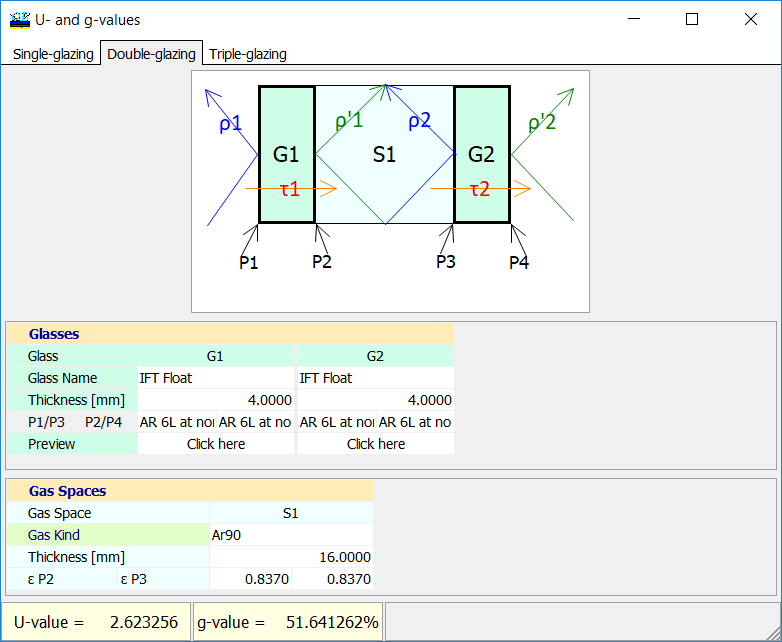

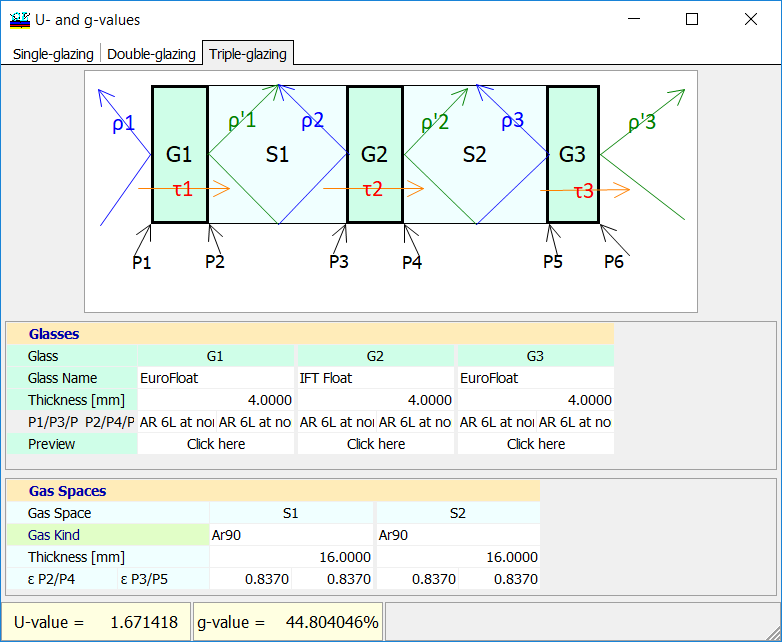

U- and g-values definitions and descriptions can be found in DIN EN 410, DIN EN 673 standards. These values are often used in architectural glass industry in order to describe quality of a glazing. In OptiLayer is is possible to consider single-glazing, double-glazing and triple-glazing configurations: |

|

|

|

|

U- and g-values option is available in OptiRE as well. In OptiRE, instead of glass configuration it is possible to upload experimental data for the evaluation of manufactured glazing performance. For this purpose you can use buttons “G buttons” at the top of selected Glass position. After clicking “G button”, an additional “Import T, R, and BR Data Files” dialog for browsing and selection the experimental data is opened.

|

| This option can be found in Results –> U- & g-value | |

|

This can be selected with tabs at the upper part of the window. For your convenience, the schematic of the glazing is shown in the middle of the window. Glass Name entries allow you to select glasses from the substrate database. Two standard glasses with the names IFT Float and EuroFloat are pre-created in the substrate database when you first open U- and g-values window. Thickness [mm] field allows you to set thicknesses of glasses. |

P1/P3, P2/P4, … entry fields allow you to set a coating from the Design database for each surface of each glass. Look at the schematic to check correct position of the surface. Coating layers are always numbered in the direction from glass. There is also a special object * Current * in the configuration list. If * Current * is selected as a coating at one or more surfaces, currently loaded in memory design will be used in this place. It allows to estimate U- and g-value dynamically in the course of solving a synthesis problem, since they are updated every time when the design is updated. |

|

Preview row contains buttons opening small windows with spectral curves for each of glasses composing the glazing. It allows quick check of correct specifications for each glass. Transmittance, Reflectance and Back Reflectance of the glass are shown. Coatings at both sides (if present) are taken into account in this Preview:

|

Gas Kind entry fields allows to select gas filling the space between the glasses: Ar90, Ar, Kr, Xe, SF6 and Air. Thickness [mm] allows you to select the thickness of the space between the glasses. ε P2, ε P3, ε P2/P4, ε P3/P5 entries specify the so-called corrected emissivity factors (DIN EN 673). U- and g-values are represented at the bottom of the window. They are recalculated every time when any of the settings is changed. |

Look our video examples at YouTube

OptiLayer videos are available here:

Overview of Design/Analysis options of OptiLayer and overview of Characterization/Reverse Engineering options.

The videos were presented at the joint Agilent/OptiLayer webinar.