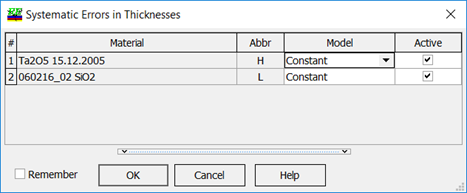

Systematic errors in measurement data may be caused by various factors, for example:

These factors may result in the shift of measured transmittance/reflectance data as a whole or in the scaling them by a factor that differs from 1. From a mathematical point of view, in the course of Systematic errors procedure only two unknown parameters are searched for. Optical coating model in this case can be described by vector \(X\): \[X=d_1+\Delta_H, d_2+\Delta_L,…,d_m+\Delta_H(L)\] |

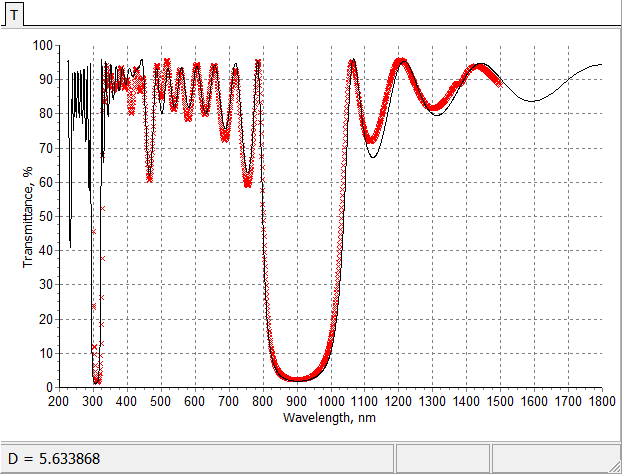

Fitting before and after application of systematic errors model (put the mouse on and out of picture) Fitting before and after application of systematic errors model (put the mouse on and out of picture) |

|

Discrepancy function is optimized with respect to systematic shifts \(\Delta_H, \Delta_L\):

\[ DF^2(\Delta_H, \Delta_L)\rightarrow \min\] |

|

|

|

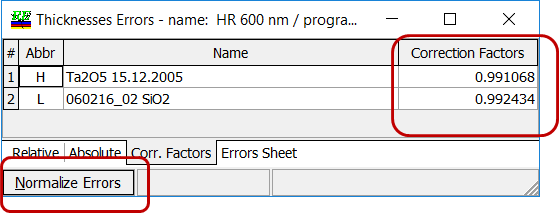

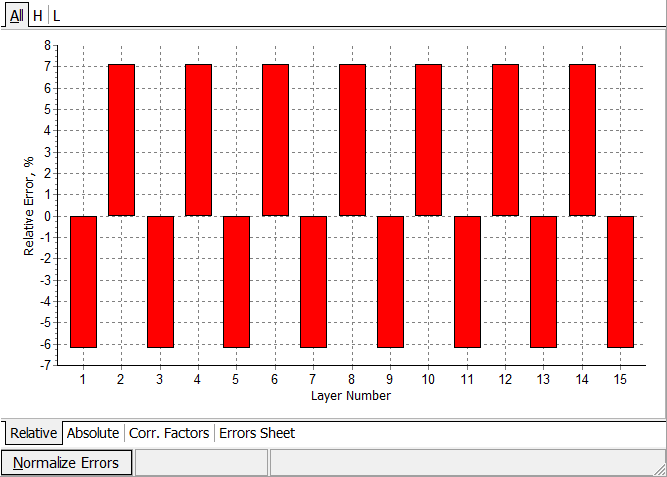

The results of the procedure are presented as Relative, Absolute errors or correction factors for layers of active materials.

Systematic errors procedure can be easily run from an external software with the help of COM Automation tool. |

OptiLayer provides user-friendly interface and a variety of examples allowing even a beginner to effectively start to design and characterize optical coatings. Read more…

Comprehensive manual in PDF format and e-mail support help you at each step of your work with OptiLayer.

If you are already an experienced user, OptiLayer gives your almost unlimited opportunities in solving all problems arising in design-production chain. Visit our publications page.

Look our video examples at YouTube

OptiLayer videos are available here:

Overview of Design/Analysis options of OptiLayer and overview of Characterization/Reverse Engineering options.

The videos were presented at the joint Agilent/OptiLayer webinar.